|

Laboratories

at BYU

|

| Wildland

Fire Laboratory

Thomas H.

Fletcher

Chemical Engineering

|

Steve Smith

Current forest fire Models are based on extensive empirical data

for dead vegetation. The models are accurate in predicting the fire

spread rate and intensity for conditions similar to the data from

which they are based but are less accurate under other conditions.

Understanding the combustion characteristics of live vegetation

may increase the overall accuracy of forest fire modeling. The lab

is designed to burn small samples (single leaf) in an environment

similar to a forest fire. The leaf sample is suspended on a cantilever-type

mass balance. A thermocouple is placed in a pinhole in the leaf.

A flat flame burner and a radiant heating panel can be pulled by

a motor to stop under the leaf. The process is captured visually

with a camcorder. The images and the temperature and mass are recorded

as a function of time through a program written in Labview 6.1.

Ignition temperature, time to ignition, flame duration, mass loss,

and flame height are determined through the analysis of the data.

By changing the moisture content, thickness, and shapes of the leaves

different ignition characteristics are observed. |

|

| Gas

Turbine Combustion Laboratory

Thomas H.

Fletcher

Chemical Engineering

|

This facility was designed to simulate the inlet conditions of

gas turbine engines. It matches Mach number and temperatures up

to 0.8 and 1200°C respectively. An auxiliary air system allows

the experimenter to seed the combustion stream with a cocktail of

particles typical of virtually any operating condition of interest

to include long-term degradation by ingestion of ambient particulate,

biomass burning, coal combustion, or any other particle-laden regime.

The express purpose of this facility is to create sample of turbine

blade materials with degradation structures typical of actual service

life but at a fraction of the cost and time. Details of this facility’s

application to the study of GT engine degradation under normal operating

conditions were presented by Jared Jensen (thesis title: “The

Development of an Accelerated Testing Facility for the Study of

Deposits in Land-Based Gas Turbine Engines) in 2004. A condensed

version of these findings was presented at the IGTI conference 2004

by Dr. Jeffrey Bons and will later be published in the ASME Journal

of Turbomachinery. |

|

| Particle

Combustion Laboratory

Larry L.

Baxter

Chemical Engineering

|

Black Liquor Combustion

Black liquor is a byproduct from the paper pulping process. It

is concentrated and burned in a recovery boiler. Black liquor burns

in droplet form. Understanding the combustion process and being

able to model the process are significant.

• Single black liquor droplet is burned in

a furnace with viewports in three orthogonal directions.

• Imaging from the viewports allows optical surface temperature

measurement and 3-D image reconstruction.

• The droplet is suspended on a thermocouple wire that allows

for droplet internal temperature profile to be measured.

• The mass loss is also recorded using a high-resolution balance.

• Intermediate-sized particle (ISP) is studied with the addition

of the cyclone separators.

• Molecular beam mass spectrometry (MBMS) is used to analyze

the off-gas of the droplet combustion.

• Model is being developed for the droplet devolatilization

and combustion.

Biomass Particle Combustion

Hong Lu

• Biomass particles commonly have aspect

ratios of 3 to 12, which cannot be adequately described using spherical

approximations for mass and heat transfer; the combustion process

may be controlled by surface area effects.

• An entrained flow reactor is used in this project, which

is electrically heated with wall temperature up to 1650 K; the temperature

profile along the reactor can be controlled separately by adjusting

wall temperatures in each of the four sections;

• This reactor provides about three seconds residence time

for biomass particle;

• Optical access is provided, which allows particle images

to be obtained in each of three orthogonal directions using imaging

pyrometers (high-speed cameras);

• With a 3D particle shape reconstruction code, the particle

shape, volume, and surface area data can be generated from particle

images;

• The reactor can provide instantaneous particle velocity,

surface temperature, size, shape, surface area, volume, and mass

loss as functions of particle residence time. |

|

| Solids

Reactions

Laboratory

Thomas

H. Fletcher

Chemical Engineering

|

Pyrolysis

and combustion of solid materials are studied in the Solids Reactions

Laboratory in a High Pressure Drop Tube Reactor and in a Flat Flame

Burner (FFB). Both facilities can operate with or without oxygen

present, and are equipped with sampling probes to separate tars

and aerosols from chars. Solid samples are analyzed for elemental

composition using a LECO 932 CHNS analyzer. ICP analysis for Ti,

Al, and Si provides tracers for verification of mass release. The

drop tube experiments can be performed at particle heating rates

of ~104 K/s, pressures from 1 to 25 atm, residence times

of 100 to 300 ms, and temperatures from 600 to 1300 K. The FFB experiments

can be operated at particle heating rates of ~105 K/s,

residence times of 20 to 150 ms, and gas temperatures ranging from

1600 to 2500 K, by adjusting the fuel (CO or CH4),

the equivalence ratio, and the flow rates. Particle feed rates in

these two reactors are low (1g/hr) to ensure single particle behavior. |

|

| Flat

Flame Burner Laboratory

Thomas

H. Fletcher

Chemical Engineering

|

Flat Flame

Burner

The Flat Flame Burner Laboratory focuses

on the formation of soot and char to determine what constitutes

these combustion products. Understanding the formation of these

undesired by-products may help reduce them in the future. Solid

and liquid samples are feed to the center of a Flat Flame Burner

(FFB). Soot and char from pyrolysis are pulled into a vacuum collection

probe which then separates the soot from the char through the use

of a virtual impactor and cyclone apparatus. These two combustion

products are collected for further analysis. They may be analyzed

to determine elemental compositions of carbon, hydrogen, nitrogen

and sulfur using a LECO CHNS-932 analyzer. The combustion gases

may also be analyzed during a run through the use of a Fourier Transform

Infrared Spectrometer (FTIR). The FTIR allows one to measure the

presence and concentration of certain molecules.

The FFB can be operated at various gas temperatures

ranging from 900 to 2500 K by changing the gas flow rates and equivalence

ratio of fuel (CO) to air. Typical residence times are from 20 to

100 ms with a particle heating rate on the order of ~105 K/s.

|

|

| Catalysis

Combustion Kinetics and Surface Analysis Laboratory

Calvin H.

Bartholomew

William

C. Hecker

Chemical Engineering

|

The

Catalysis, Combustion Kinetics and Surface Analysis Laboratory focuses

research on coal char oxidation, catalysis, and the surface properties

of catalysts, coals and chars. The principal objective of this work

is to develop models and data which relate oxidation rate parameters

for coal chars to their chemical and surface properties. Facilities

include:

- A drop-tube

reactor which utilizes two-color pyrometry for measuring particle

temperature, velocity and size.

- A char

preparation facility utilizing a flat flame burner for preparation

of medium and high temperature chars.

- A Micromeritics

surface area analyzer (N2 and CO2).

- A Nicholet

730 FTIR spectrometer.

- Two thermogravimetric

analyzers.

- A Quantachrome

helium micropycnometer (to measure true densities).

- Ovens/furnaces

for preparation and pretreatment of catalysts and chars.

- Volumetric

vacuum analyzers used in measurements of surface areas, pore

size distributions, and densities.

- A Mössbauer

spectrometer for analysis of iron species.

|

|

| Combustion

and

Reactions Laboratory

Dale R. Tree

Mardson

Q. McQuay

Mechanical Engineering

|

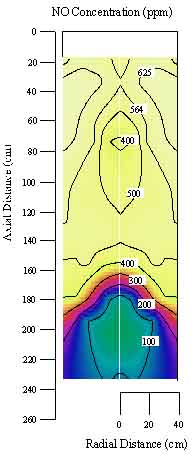

The

Combustion and Reactions Laboratory is dedicated to the experimental

research and testing of various combustion phenomena. The laboratory

includes two pulverized coal reactors, a particle dispersion reactor,

and a gas turbine burner. Supporting diagnostic equipment is also

maintained and available for numerous combustion and coal-related

measurements.

- The controlled

profile reactor (CPR) is a 1 MW, down-fired, pulverized coal

reactor with optical and conventional instrumentation access.

The reactor allows for the testing of novel combustion concepts

(such as swirl, reburning, etc.), the study of combustion through

detailed measurements, and the validation of combustion models

through a simplified reactor geometry. Support equipment for

the reactor includes Pitot tubes, suction pyrometer and gas

analyzers.

- A smaller

0.1 MW laminar flow reactor with staged combustion is used to

generate ash and deposits for studies on slagging and mineral

matter in coal.

The

laminar flow reactor and the CPR can be operated with natural gas

or pulverized coal and potentially other experimental fuels.

A high pressure

particle dispersion chamber is used to study the trajectory of coal

particles in high velocity gaseous streams.

Also

included in the Combustion and Reactions Laboratory are an optical

particle size analyzer and a small chemistry lab where ultimate

analysis, coal moisture and gas chromatography can be performed. |

|